Thanks to a patented dual Variable Frequency Drive (VFD) motor, our SMART sootblowers have the ability to change directions multiple times during a single cleaning event. Ours is the only sootblower that allows for independent traveling and rotational speeds, providing the dynamic ability to clean based on the severity of buildup in a given area.

SMART Sootblower are paired with our SMART Control™ suite. The module integrates into the main system for basic functionality, with a user-friendly operator interface. SMART sootblowers can be programed to run in a closed-loop control mode for optimum performance. This allows cleaning to occur when and where it’s needed, with real-time data from our SMART Gauge™ and SMART Convection™ systems.

- Targeted sootblowing

- Increased boiler efficiency

- Dynamic cleaning

- Eliminates slag/tube erosion related shutdowns

SMART Sootblower can also use water as cleaning media to further improve targeted cleaning effectiveness. Water cleaning is extremely effective in removing tough slagging where steam cleaning is not sufficient. The water jet from SMART Sootblower nozzle is able to only clean the plugging area between boiler tubes so that the boiler tubes will not be damaged.

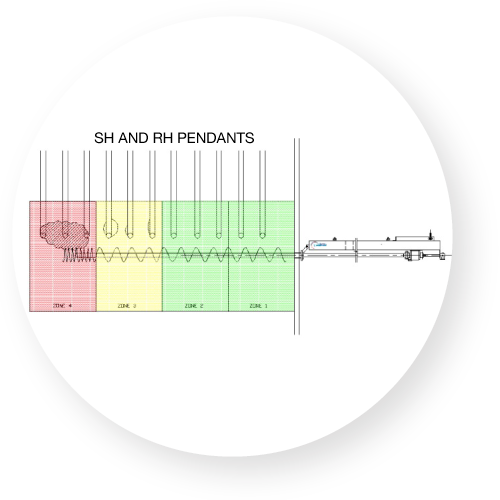

The lance is equipped with a single nozzle, instead of the conventional two nozzles, to create a single jet directed exactly where the deposit is located with little to no water/tube interaction. A small pump skid is used to increase the service water to 100 psig and supply it to the sootblower for cleaning. The sootblower is programmed with a zone based cleaning to allow the sootblower to stop between each tube bank in the path to keep the tube passages clean and clear.