PORT CLEANERS

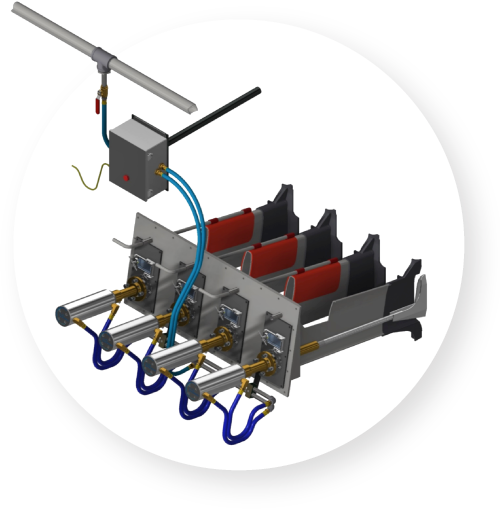

Single Stroke Cleaner 3

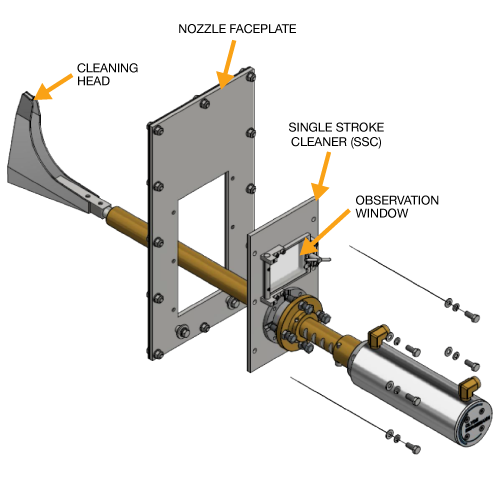

Designed with simplicity in mind, the Single Stroke Cleaner houses a robust 4” diameter air cylinder to clean the toughest buildup. The cleaning head is designed for maximum airflow while closely matching the port opening profile and ultimately keeping the port clean.

- Proprietary air cylinder designed for high heat applications

- Large diameter air cylinder can clean the most difficult build up

- No exterior moving parts

- Large opening window allows for visual inspection

- Large cleaning head allows maximum air flow

- Cleaning head made with high temperature stainless steel and provides long service life

- Cleaning head designs for any size and shape port opening

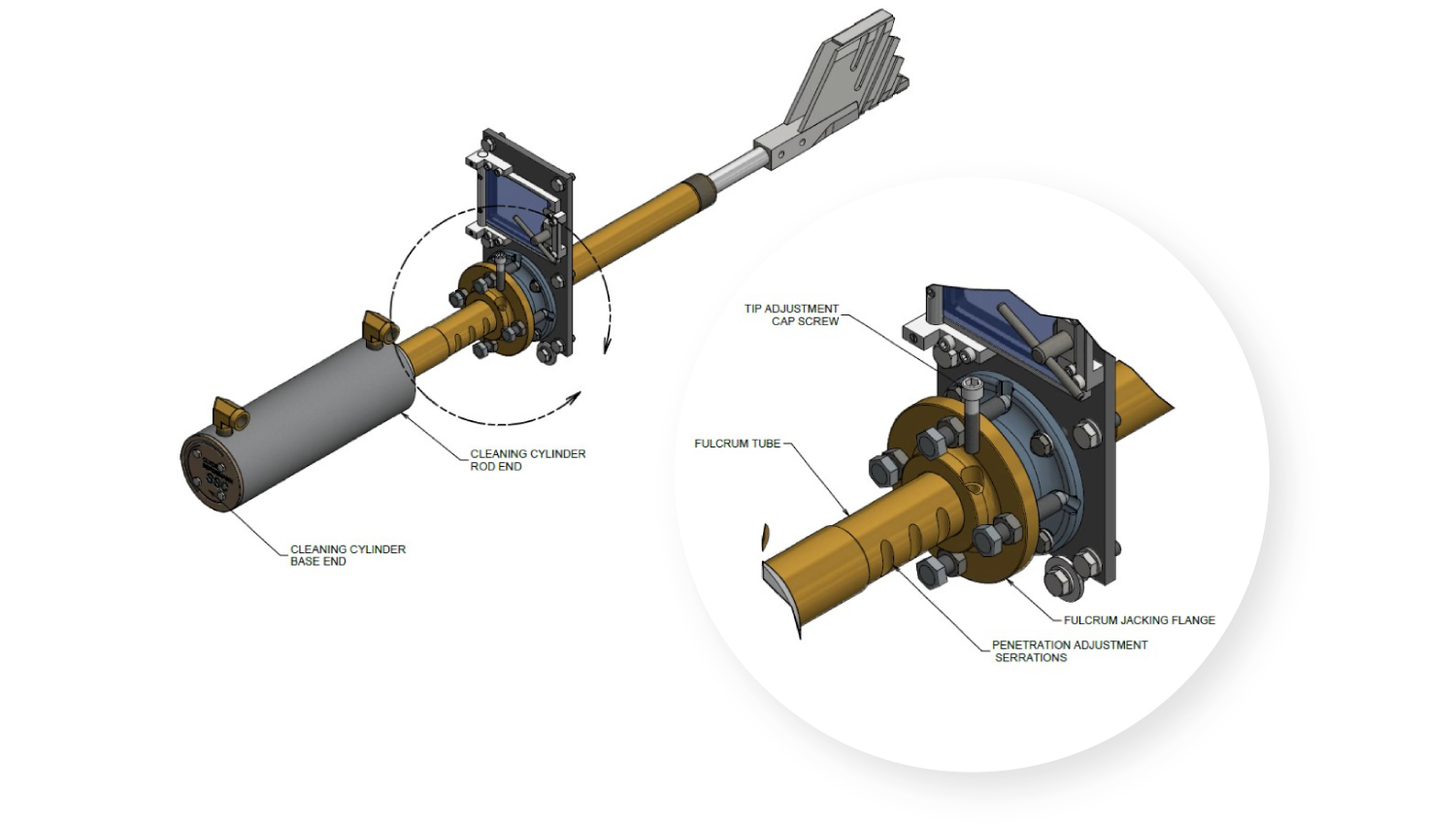

New Feature: Adjustable Fulcrum Tube

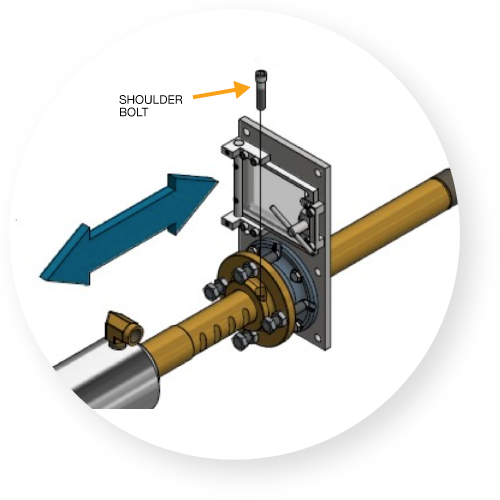

A revolutionary design feature with the SSC 3 is the cleaning head penetration can be adjusted further into or out of the boiler without removing the cleaner. Adjusting the cleaning head penetration is possible with the advent of the Adjustable Fulcrum Tube. To adjust the cleaning head penetration simply remove the shoulder bolt as shown in the image below. The fulcrum tube has adjustable segments in 1-inch increments and allow a total of 8-inches of adjustments.

- Easily adjust cleaning head penetration

- Safely adjust cleaning head without exposing workers to boiler hazards

- Spherical trunnion provides 100% seal against windbox combustion air

- Self-locking spherical design will not loosen.

Why is the adjustable fulcrum tube needed?

Over time, the cleaning head will burn back and at some point will require replacement. With the recovery boiler in operation, cleaning head replacement has numerous safety concerns and requires careful planning.

Even 1-inch of burn back on a cleaning head will impact air flow and eventually affect boiler performance. At the secondary air level, eyebrow formations can disturb airflow and in some cases block airflow altogether. With the “Adjustable Fulcrum Tube”, cleaning head penetration can be adjusted safely without exposing workers to this dangerous environment.

Even 1-inch of burn back on a cleaning head will impact air flow and eventually affect boiler performance. At the secondary air level, eyebrow formations can disturb airflow and in some cases block airflow altogether. With the “Adjustable Fulcrum Tube”, cleaning head penetration can be adjusted safely without exposing workers to this dangerous environment.

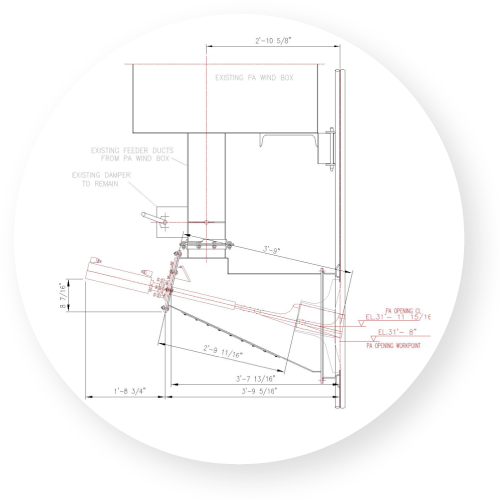

Typical Design

Specifications

- Air Cylinder 4-inch (100 mm) diameter and 8-inch stroke (200 mm)

- Cleaning head made with high temperature stainless steel.

- Electrical 110 volts, 60 Hz solenoid valve

- Control panel stainless steel Nema 4X

- Air requirements 90 psi (6 bar) Instrument air recommended