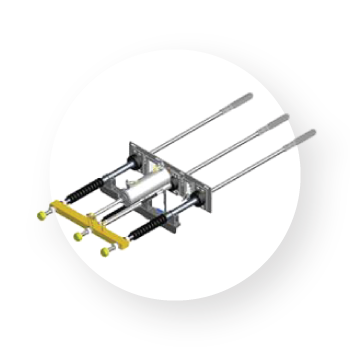

- Multi-rod cleaner

- Single Stroke Cleaner

- Automatic Port Dampers

- Port Castings

- Draft Pipe Cleaner

- Windbox replacement

Boiler. The recovery boiler is an unforgiving environment and it is important to select a product and provider who can deliver products to withstand these extremes. Clyde Industries professional series was developed specifically for this harsh environment.

Reliability. Never settle for good enough! At Clyde Industries, we are continually improving our products. Do not accept cheap imitations or off the shelf air cylinders with mediocre seals. Our air cylinders are designed for use in a recovery boiler; we fabricate and assemble each air cylinder to exacting standards.

History. The multi-rod cleaner has been in productions for over 30 years and for good reason. The indexing style cleaner continues to remain cost effective while keeping the combustion ports clean.