Rapping

System

System

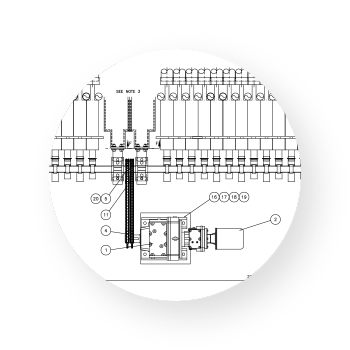

Mechanical Rapping Cleaning Systems are devices used to impart shock forces to a bank of boiler tubes so that the bond is broken between the tube and dry types of slag and ash that collect there. Tube headers or mechanical ties are used to couple adjacent tubes in each row so all tubes in the bank receive a shock blow when the hammer weight strikes the ram. The dislodged material falls to a collection hopper while a thin residue layer remains on the tube surface acting as a protective coating minimizing corrosion.

Mechanical Rappers are typically employed in refuse fired units in areas where dry slag is encountered. Soot Blowers are avoided because of erosion and/or corrosion potential due to blowing the tube surfaces bare with subsequent corrosive deposits collecting.

- Extended boiler-operating time

- Lower cost of operation and maintenance

- Increased efficiency in evaporators, superheaters and economizers

- Operational feedback to the control room

- Maximized thermal efficiency and reduced gas exit temperatures